Rockwell hardness test

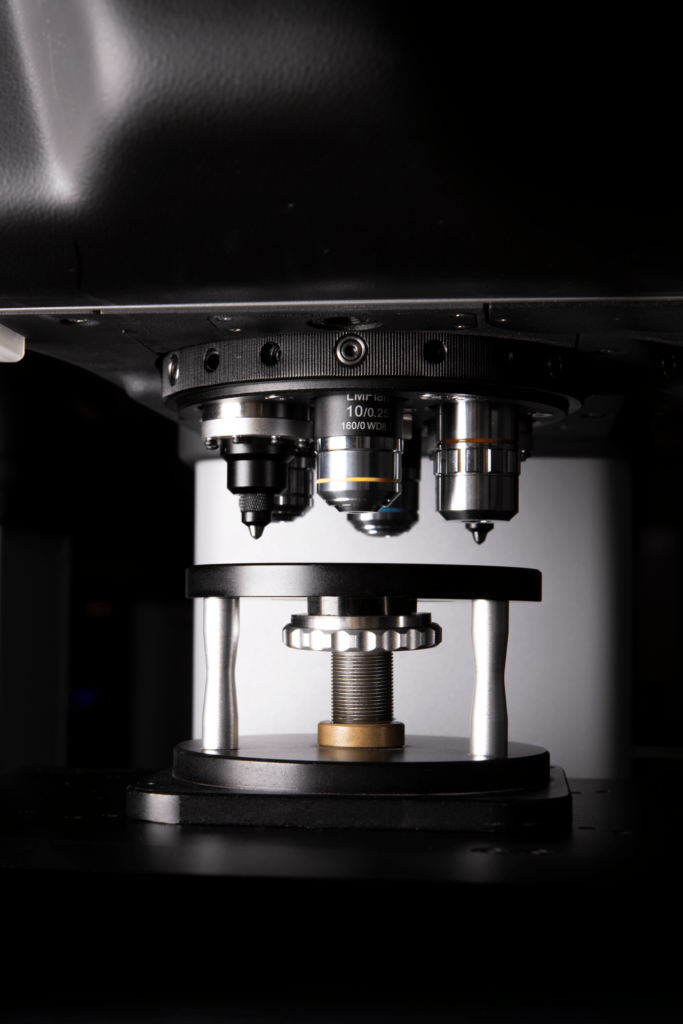

The Rockwell hardness test of materials, almost all metals and plastics, is based on an indentation hardness test. An indentation hardness test is a measure of the deformation caused on material due to its penetration by a specific type of indenter. The general test procedure is the same regardless of the type of Rockwell machine used. The specific required standards and procedures are provided by internationally accepted standards writing organizations such as the American society for testing and materials (ASTM) and the international standards organization (ISO).

Advantages of the test.

The numerous advantages that accrue from the test method have increased its adoption worldwide. The simplicity in operating any Rockwell machine cancels the need of a highly-skilled operator. Execution of the test is fast, affordable and sustainable, in that it leaves a small indention on the material. Furthermore, the Rockwell hardness test in line with other material properties can provide key properties of the material such as its ductility, tensile strength and wear-resistance.

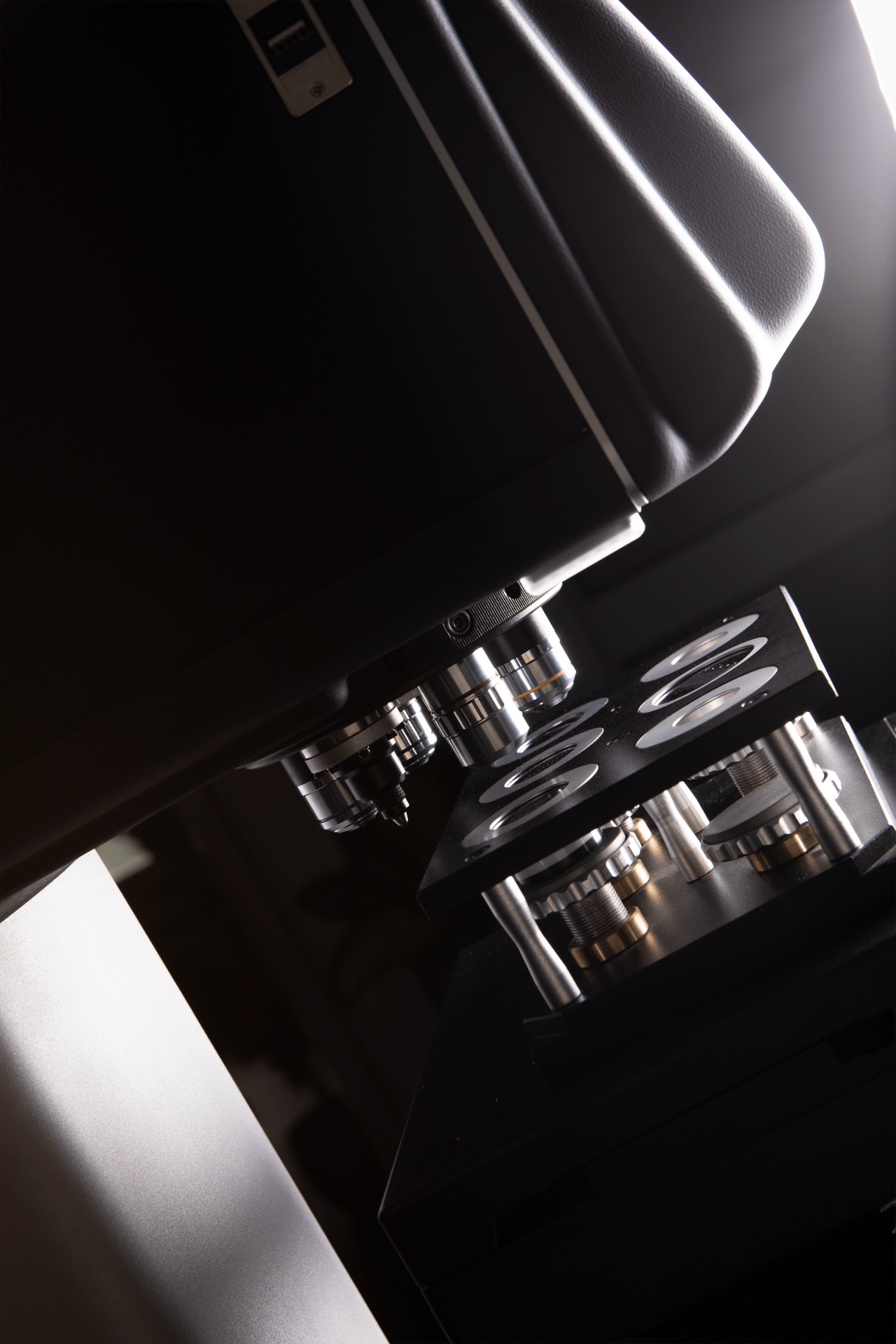

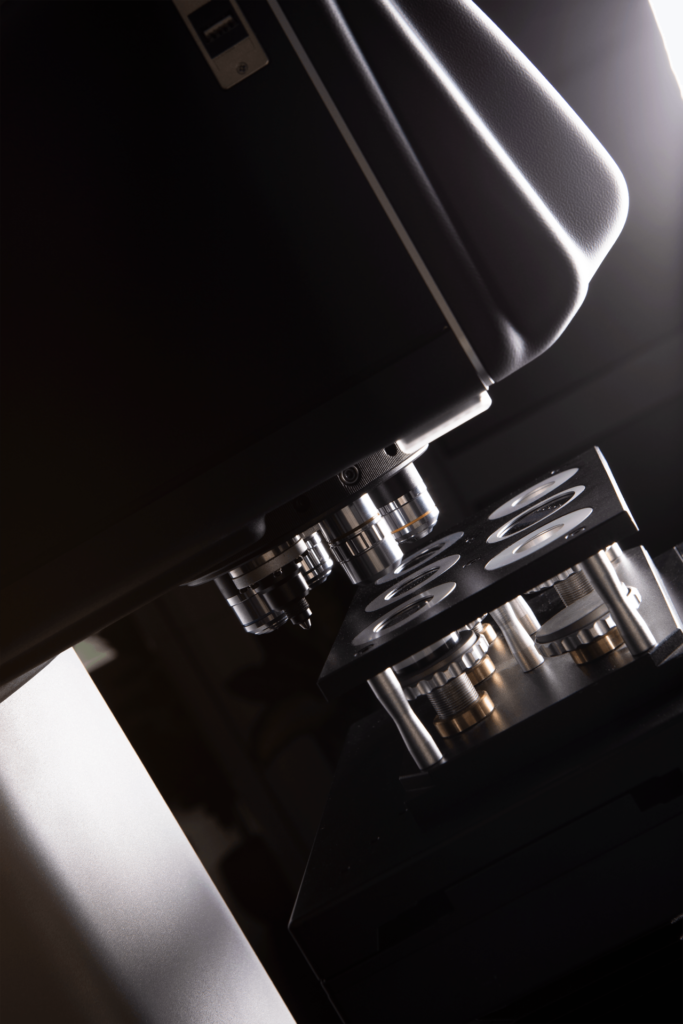

This test comes in handy in process and quality control of materials and for approval testing of commercial products. The application of Rockwell hardness machines is in almost every testing environment, from the hot, oily surroundings of some manufacturing facilities, to environmentally-controlled laboratories.

Operating Rockwell hardness machines varies from model to model. The user should therefore read and follow the recommended operating procedures found in the manufacturer’s manual.